Add to Cart

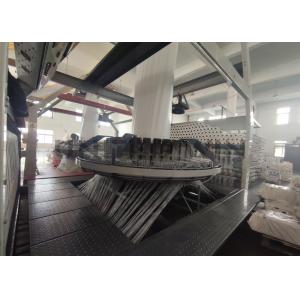

SBY-850x6S Six Shuttle Circular Loom PP Woven Sack Making Machine

Description:

The circular loom machine is used for weaving PP/PE flat yarn to be woven fabric in roll. We can make all type Circular Loom such as 4-shuttle Circular Loom, 6-Shuttle Circular Loom, 8-shuttle Circular Loom, and 10shuttle Circular Loom. Circular Loom can make PP woven fabric for cement bag, rice bag, wheat Woven Bag , Jumbo/Container/FIBC Bags, sugar Woven Bags.

Main technical Datas:

| ltem | SBY-850x6S |

| Number of shuttles(pcs) | 6 |

| Nolding width of cloth | 300~850mm |

| Number of warp | 720 |

| Weft densith | 20-75picks/100mm |

| Running speed of main motor | 135-150r/min |

| Power of main motor | 3kw |

| Specification of bobbin(ID×L) | 28-38x230mm |

| Max. weft bobbin diameter | 1155mm |

| Overall dimension(L×W×H) | 10500x2800x2920mm |

| Weight of machine(about) | 2000kg |

Machine Details:

1. How long will your engineer reach our factory?

Within one week after everything ready (machine arrival your factory, non-woven material, power source, air compressor etc. Prepared)

2. How many days will you finish installing?

We will finish installation and training within 15 days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 150USD one day per person.

4. How long is your machine's warranty period?

All our machine has one year guarantee for electricity parts and two years guarantee for mechanism, starting from finished installation.

5. How could you do if the parts broken within warranty?

We would express the free replacement parts during the warranty date